Upstream Development

Process Optimization and Characterization

Comprehensive Optimization Strategies and Work Allocation

Based on our rich experience in biological development especially in the field of biosimilars, the upstream and downstream teams collaborate closely to optimize process yields and qualities. The optimization strategies and work arrangements are designed to balance yield, quality and cost from a general perspective. The optimizations include but are not limited to increasing product yields, modulating charge variants and monomer purities, and regulating glycosylation.

Rational Design of Process Characterization

Aton adheres to the concept of Quality by Design by persistently exploring more reasonable process characterization strategies. Risk analysis and assessment are integrated into whole product lifecycles. Scale-down models are continuously improved and advanced statistical analysis is used. Bioprocess is continuously monitored to ensure the effectiveness of process control strategies.

Case

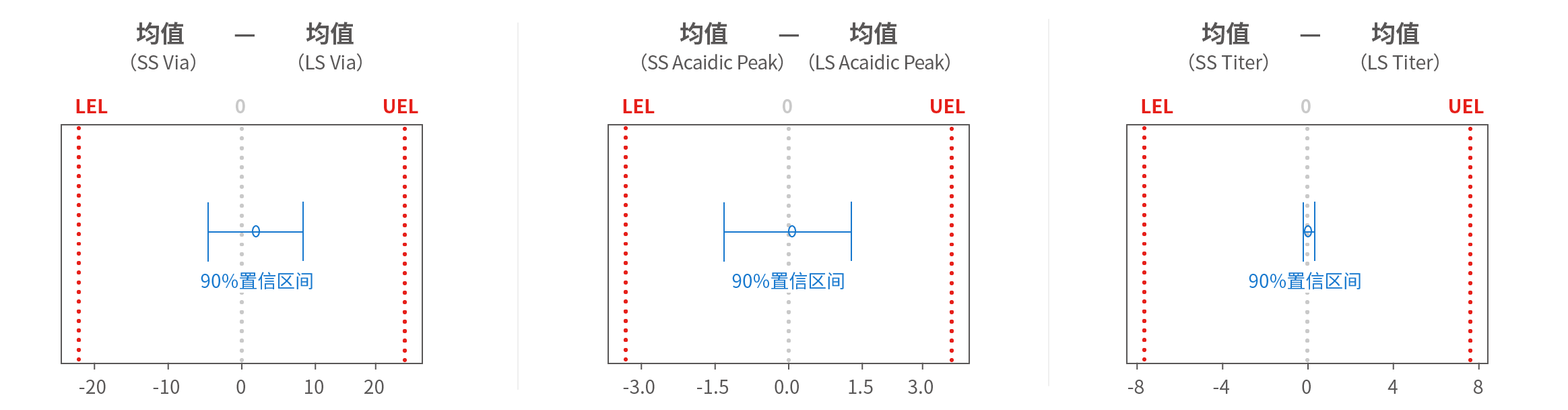

Case 1:Establishment of Scale-down Model

Content: Equivalence qualification of pCQAs and KPAs

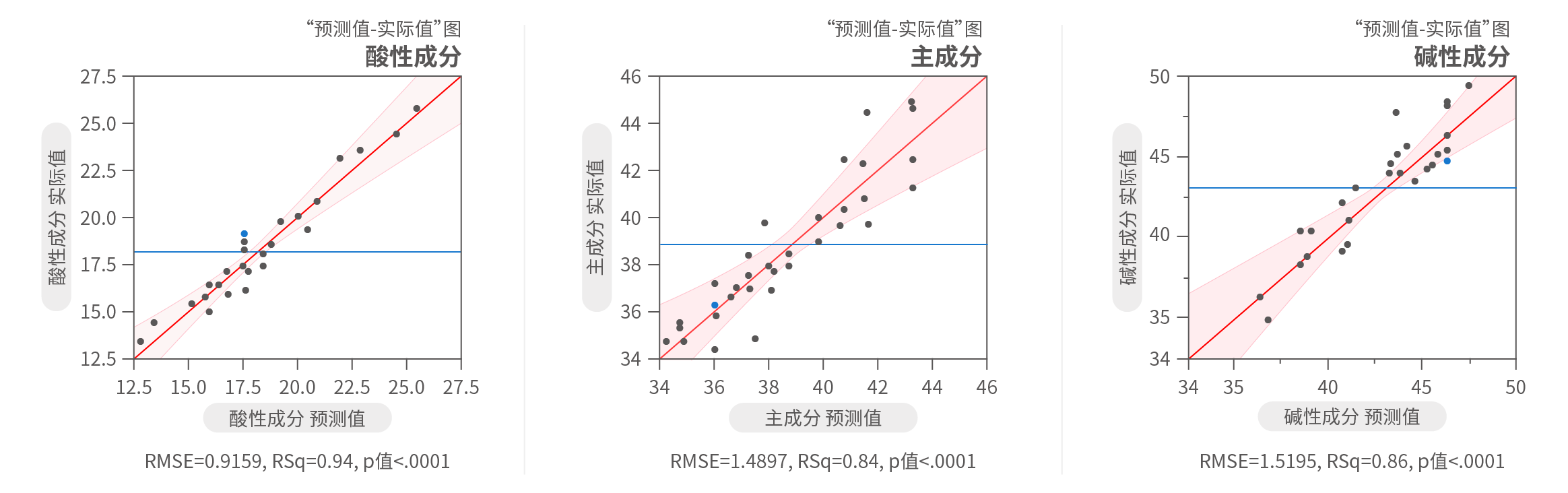

Case 2: Process Characterization Study

Content: Model fitting of Central Composite Design for Charge Heterogeneity Analysis

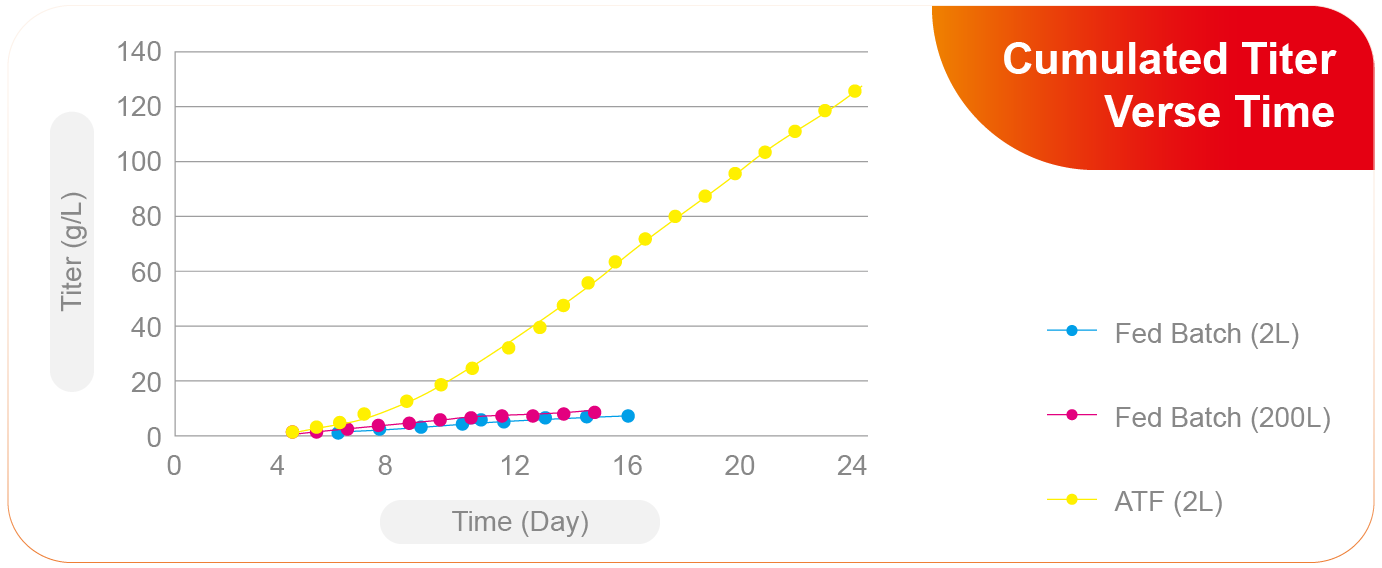

Compatibility with Traditional Fed-batch and New Generation Processes

Compatibility with Various Process Strategies

-

Not only traditional fed-batch process, Aton also has rich experience in high-density process intensification and perfusion process development.

Effective Enhancement of Process Yield

-

The new process effectively increased antibody yield by ten folds verse fed-batch process.

-

The new process is robust enough for manufacturing transfer.